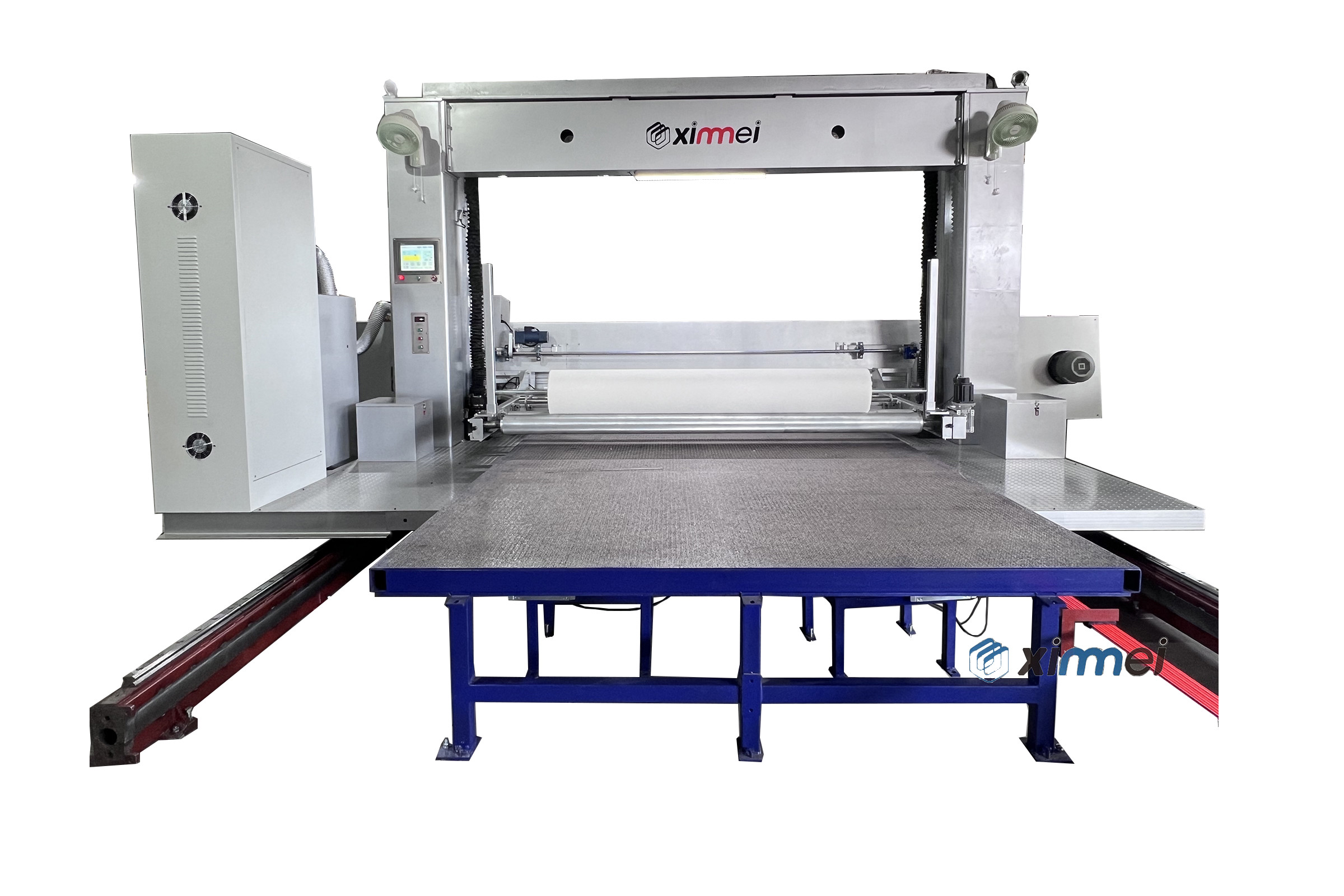

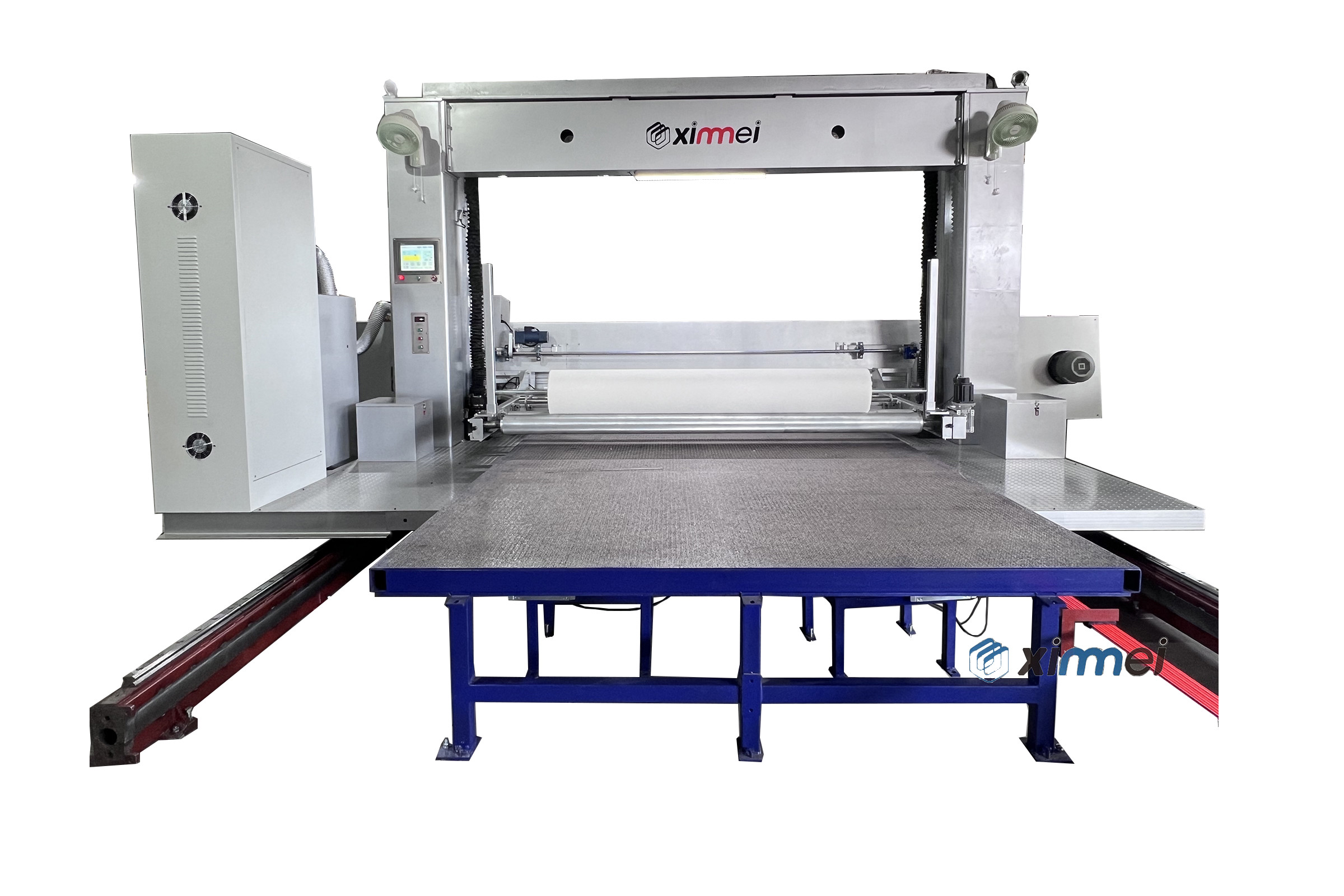

Siemens electronic Control C517 PU long Foam block Cutter with

Linear Guide and Auto Knife Feed sharpening peeling auto roll up

winder for laminating

Overview

1. The C517 horizontal cutting machine is the latest high-precision

long foam horizontal cutting technology equipment, suitable for

continuous vacuum cutting of infinitely long foam blocks.

2. The machine is equipped with servo motors(Siemens or Delta),

linear guides(Hiwin), and a vacuum suction worktable(pre on and

auto off), achieving precise control, smooth movement, and safe

material handling.

3. An automatic knife entry and sharpening system ensures a

seamless cutting process, featuring high precision, low noise, fast

cutting, and high efficiency.

4. The equipment has intuitive control and robust safety features,

suitable for industrial and commercial applications, capable of

handling various soft and hard foam materials, and adaptable to

different cutting modes and thicknesses.

5. The modular structure of the C517 facilitates maintenance and

upgrading, ensuring a leading position in cutting technology and

providing unparalleled performance and reliability for foam

processing operations.

Polyurethane (PU) Foam

Polyurethane foam is commonly utilized in various applications,

including:

- High Resiliency Flexible Foam Seating

- Rigid Foam Insulation Panels

- Microcellular Foam Seals and Gaskets

- Durable Elastomeric Wheels and Tires

- Automotive Suspension Bushings

- Electrical Potting Compounds

- Seals and Gaskets

- Carpet Underlay

- Hard Plastic Parts (such as those used in electronic instruments)

Flexible polyurethane foam serves as cushioning for a wide range of

consumer and commercial products, including bedding, furniture,

automotive interiors, carpet underlay, and packaging. This

versatile foam can be manufactured in various shapes and firmness

levels.

Key Properties:

- Lightweight and Durable: Provides support while remaining comfortable.

- High Tear Resistance: Maintains integrity under stress.

- Resistance to Water, Oil, and Grease: Suitable for various environments.

- Excellent Electrical Properties: Ideal for electrical applications.

- Wide Resiliency Range: Offers options for different applications.

- Strong Bonding Properties: Ensures durability in assembly.

- Performance in Harsh Environments: Stands up to challenging conditions.

- Mold, Mildew, and Fungus Resistance: Enhances longevity and safety.

- Variety of Color Options: Available in multiple colors for aesthetic flexibility.

- Economical Manufacturing Process: Cost-effective production methods.

Overall, polyurethane foam is a versatile material with numerous

applications across different industries.

| Model | C517 |

| Cutting thickness | 0.5-70mm |

| Cutting width | 2200mm |

| Cutting height | 1300mm |

| Cutting speed | 0-120m/min |

| Cutting tolerance | 0.5-3mm ±0.05mm |

| Main motor power | 25kw |

| Main unit weight | 8T |

| Main unit dimensions | 6500 L*3000 W*2600 H mm |

Our machines have been meticulously designed, from the choice of

structural materials to mechanical construction, as well as the

selection of mechanical components and electrical equipment.

Furthermore, through repeated adjustments, we ensure that they can

meet the precise cutting requirements of the above-mentioned

industrial factories after installation. At the same time, our

machines are built for long-term durability, ensuring that the

design accuracy remains stable for 10 years.

CONFIGURATION

Ball screw : Taiwan Hiwin

Bearing : Japan NSK or Sweden SKF

Siemens touchscreen + Siemens PLC + Siemens servo motor or Delta

Worktable :Aluminum alloy surface vacuum suction

Linear guide : Taiwan hiwin or Japan THK

Vacuum suction steel or aluminum worktable (pre on and auto off)

SALES AND SERVICE NETWORK

Successful Project

FAQ

・The brand name of this machine is Xinmei.

・The model number of this machine is C517 manufactured in Qingdao,

China.

・The payment terms for this machine are TT and L/C.

・The delivery time for this machine is 80 days after receiving the

agreed deposit.

・Packaging Solutions Overview

We offer a range of packaging solutions including:

- Plywood Boxes

- PVC Stretch Film

- EPE Pearl Cotton Film

Our packaging is specifically designed to be suitable for container

shipping, ensuring your products are well-protected during transit.

・Installation and Support

We provide comprehensive guidance for installation and

commissioning. Should you require local assistance, we are

available to help without any issues.

・Our Commitment

We adhere to the principles of:

- Quality First

- Reasonable Pricing

- After-Sales Warranty

Consultation services

Competitive products

Continuous

Auto Foaming Line Long Foam Block Horizontal Peeling Machine ±0.2mm

Cutting Tolerance (foamcutting-machines.com)

| Cutting width | 2200mm |

| Skiving thickness | 1.5-70mm |

| Cutting height | 1300mm |

| Moving speed | 0-60m/min |

| Motor power | 14.89kw |

| Machine weight | 2800kg |

| Overall size | 4300*2100*2200mm |

Your visit will definitely provide valuable insights. If given the

opportunity, I would love to listen to your insights. Thank you for

your proposal!